Draffin Street Furniture prides itself on giving you the choice of materials to use on all of our products. Batten choice is important. It needs to fit certain criteria, and while appearance would be number one on the list for most customers, there are many more factors that will sway the choice towards something more appropriate for the application.

Location

A great starting point for batten choice is to look at the area the furniture will be installed. While urban settings will suit one material, bushland settings may not suit the same. Timber is almost always suitable in most urban or bushland settings but may be dependant on the style of the furniture also. Or will the furniture be installed in a coastal location? Maybe even an area that experiences regular extreme weather like high temperatures, or snowy alpine settings? These scenarios will greatly change the material choice if you want the furniture to look and perform at it’s best year after year.

Sustainability

The move towards more sustainable materials has prompted furniture manufacturers to search for batten material alternatives. And while many materials have been promoted as more sustainable than others, none will match the sustainability of wood, provided it is sourced from a sustainable plantation. Many manufactured materials have changed their manufacturing processes to include recycled elements, whether partly or wholly which is great. However, the process of recycling waste product into new materials usually leaves a large carbon footprint, can be costly, laborious and potentially harmful to our environment as well. None will match woods ability to capture carbon.

View our sustainable materials

Cost

Batten material varies in price. A lot of the variance in costs are due to how the material is sourced and manufactured. Some batten materials can be made economically like aluminium (one of the worlds most plentiful metals) that uses a mix of newly extracted materials and efficiently recycled materials. A small amount of man hours is required to produce aluminium once the facilities to manufacture it are set up. While timber needs to be grown in large plantations, then harvested and finally milled. The effort involved to produce both is very different.

Another cost factor to include is the ongoing maintenance involved to keep the furniture looking good after it is installed. If the materials naturally deteriorate due to weather and wear, a program of regular maintenance is required.

Strength and Durability

All batten material choices we offer are tried and tested to endure the daily rigours of public life. They are chosen to withstand excessive weight and general abuse and the ability to recover from it, whether it needs to be repaired or replaced or even in some cases can self repair. Public furniture must endure this wear and tear to remain safe and usable for the whole of it’s service life.

Batten Material Selection

Below are the standard batten choices Draffin Street Furniture offer on the majority of our products. Some batten profiles are not available for all materials. Our product pages won’t offer these materials if this is the case. Please ask if you cannot find it as we may have missed it or we may have found a new option.

Timber

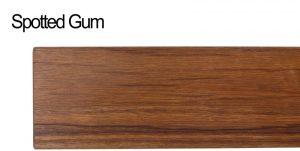

Spotted Gum – a dense timber selected for it’s durability and wavy grain characteristics that produce an attractive ripple effect. Weather protected using Intergrain Ultradeck Timber Oil. We recommend maintaining the finish using the same product. This ensures long life for the furniture. All timber material at Draffin Street Furniture is PEFC certified to assure the material has been sourced sustainably. Our current supplier Mathews Timber is PEFC certified.

Pros

- Sustainably produced

- Very dense

- Timber characteristics

- Highly durable for outdoor applications

- Strong, long spans between supports

- Readily available

Cons

- Like all timber Spotted Gum is prone to splitting and cracking if not regularly maintained

- Inconsistent Colour and Grain (part of the natural charm of timber)

Composite Timber

Enviroslat – Walnut – Manufactured to mimic timber, this batten material uses a mixture of recycled plastic and recycled timber waste (recycled cellulose (rice husks and hardwood flour) bonded together with some virgin materials and glues.

Pros

- Sustainably produced

- Cost effective

- No maintenance

- Uniform finish

Cons

- Not as strong as timber products and may require extra batten support. (Our furniture products will be engineered to accommodate the strength of the battens)

Aluminium

An economical material that is also low maintenance. A strong, consistent product with a smooth finish. Aluminium also has the ability to cool down quickly after exposure to direct sun.

Pros

- Uniform look

- Strong, long spans between supports

- No maintenance

- Durable

- Aluminium can be powdercoated for an entirely different look

Cons

- Environmental impact

- Appearance does not suit all applications

Timber-look Aluminium

Timber-look Aluminium is the best of two worlds. It looks like wood but has all the longevity and low maintenance of aluminium. Rot resistant, pest resistant and non combustible. The same aluminium battens above are coated in a hard wearing powdercoated STF primer and a sublimation film (wood grain pattern) is baked into the primer to create an impressive mar resistant finish. Available in 3 varieties:

Pros

- Consistent timber appearance

- Strong, long spans between supports

- No maintenance

- Durable

Cons

- Environmental impact

Batten Guide

We have compiled a detailed batten guide you can download here:

The batten materials above cover most applications and allow you to make a choice that best suits your space, the environment, your budget and your style. Talk to our expert sales team if you need more advice on choosing battens for your project.