Below is a compiled note on the use of stainless steel in outdoor street furniture applications. A handy .pdf guide has also been compiled that has relevant stainless steel information that pertains directly to the custom options Draffin Street Furniture provides on products. Download the guide »

Below is a compiled note on the use of stainless steel in outdoor street furniture applications. A handy .pdf guide has also been compiled that has relevant stainless steel information that pertains directly to the custom options Draffin Street Furniture provides on products. Download the guide »

Everyday we use stainless steel, from the spoon we use at breakfast – to stacking the dishwasher at night. Stainless steel also plays a major part in urban street furniture. Generally, stainless steel is specified for its extreme durability or attractive finish. However, stainless steel is also a cost effective option when taking the full life cycle into account. It is one of the few materials that will outlast the design of the furniture piece. Other commonly used materials like timber and recycled plastic can last for long periods in the right conditions but are prone to fading and cracking.

Draffin Street Furniture is a member of ASSDA , the Australian Stainless Steel Development Association. ASSDA focuses its efforts in fostering the understanding and use of stainless steel by developing the competence and efficiency of the industry through promotion, education and training. The provision of technical advice therefore allows us a thorough understanding of this material.

Some of the advantages of Stainless Steel

- Sleek modern aesthetics

- Very high resistance to corrosion

- Easy to clean and sanitise

- Easy to remove graffiti

- Long life cycle, 20 years plus

- Highly recyclable

- Little to no ongoing maintenance

A Financially Sensible Decision

Although material costs are slightly higher than coated mild steel, the overall ‘life cycle’ cost can often be substantially less, making stainless steel outdoor furniture a sound economic decision. Typically, marine grade stainless steel furniture pieces have double the service life when compared to mild steel and aluminium products.

Environmental Impact

Stainless steel is one of the few materials that is 100% recyclable indefinitely. Stainless steels longevity and minimal maintenance makes it a more sustainable option than alternative materials such as aluminium.

The Basics

Stainless steel is a generic term for a family of corrosion resistant alloy steels containing 10.5% or more chromium.

All stainless steels have a high resistance to corrosion. This resistance to attack is due to the naturally occurring chromium-rich oxide film formed on the surface of the steel. Although extremely thin, this invisible, inert film is tightly adherent to the metal and extremely protective in a wide range of corrosive media. The film is rapidly self repairing in the presence of oxygen, and damage by abrasion, cutting or machining is quickly repaired.

Stainless steel is not a complicated material to work with, but it is important to understand the basics when specifying.

Types of Stainless Steel

For most applications within the street furniture industry, austenitic type stainless steel is used. Depending on what the street furniture will endure out in the Australian environment should determine the type of stainless steel you will require.

304

A commonly used highly durable material, 304 is 18% chromium and 8% nickel (18/8). 304 is often used in indoor and some outdoor applications but isn’t really suitable for coastal areas or other aggressive environments. It will retain its structural integrity but may show signs of unsightly surface corrosion known as tea staining.

316

Commonly known as marine grade stainless, 316 is 18% chromium and 10% nickel (18/10). The additional nickel content adds further resistance to corrosion. Suitable for marine and other aggressive environments, 316 is the best choice for outdoor furniture in harsher conditions.

Welding

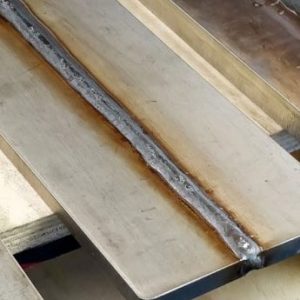

There are typically two types of welds used when fabricating stainless steel.

MIG Welding

Metal Inert Gas, or MIG welding is a fast and easy method of welding. Rollers feed continuous filler wire through a contact tip that melts the wire and parent metal together. MIG welding is suitable for hidden areas but isn’t as controlled and neat as TIG welding. It is prone to issues like contaminated welds and spattering.

TIG Welding

Tungsten Inert Gas, or TIG welding is a stronger welding technique. Utilising an electric flame torch, TIG operators can precisely control heating of parent metals and manually feed filler wire as required. TIG welding produces a deeper penetration, smaller welds and is visually appealing.

Surface Finishes

Surface finishing is the last step in stainless fabrication. It’s what separates a good job from a great job. Contaminants can stain metal surfaces if it has grooves. Hence, the smoother the surface finish the greater the corrosion resistance.

Mill Finish

Mill finish is the steels natural state straight off the production line. Best used for applications where the finish is not a factor, such as a hidden framing.

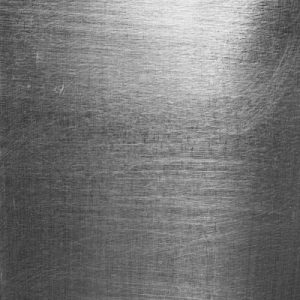

Brush Finish

Brush finish uses mechanical abrasion to create a shiny finish and embed a directional grain into the surface. Draffin Street Furniture machines brushed surfaces to a <0.5um grade, aiding corrosion resistance.

Bead Blasted

Bead blasting creates a lux, uniform, non directional finish that is slightly textured. This creates a softer, more subtle look while still retaining excellent anti-corrosion properties and all the other benefits of stainless steel. This finish is fast becoming popular as an architectural finish, suitable for modern and urban settings.

Mirror Finish

Mirror polish involves buffing the steel surface to achieve a reflective finish. Often used for aesthetic reasons, this finish also has other advantages such as being easy to wipe clean.

Pickle and Passivation

Using chemical pickling removes all surface contaminants post fabrication. The process can remove heat tint and other heavy, tightly adhering oxide scales that form during high-temperature operations such as heat treatment or welding. Passivating accelerates the production of the passive layer which increases corrosion resistance, but which is generally not effective in removal of heat tint or oxide scale. It is normally done on a part in its final machined geometry.

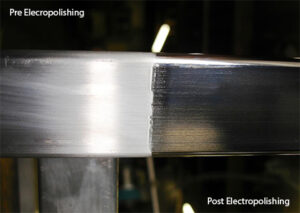

Electro Polish

Also known as reverse plating, this process removes any flaws, embedded impurities and reduces the surface roughness by levelling micro-peaks and valleys, improving the surface finish. As a result, electro polish offers one of the highest forms of corrosion resistance. Be sure to ask for this option should you need maximum stainless steel corrosion resistance.

Draffin have a long history of using stainless steel for outdoor furniture. We love to use our experience and expertise to create exceptional solutions. If you wish to discuss how you could use stainless steel in your latest project, our friendly designers are on hand to answer any questions.